We can supply professional support from machine to chocolate making

We provide OEM service and life-time after-sales service all over the world

●Specification:

| Item No | neste1000/neste2000/neste3000/neste4000 |

| Machine Capacity(kg/8 hours) | 800-1500kg/2000kg/2500kg/3000kg |

| Speed(n/min) | 10-20 stroke |

| Chocolate Shape | more than 100 kinds selected by customer |

| Certification | CE |

| Customization | Customize logo(min order 1 set)

Customize packaging(min order 1 set) |

| EXW Price | / |

●Main Introduction

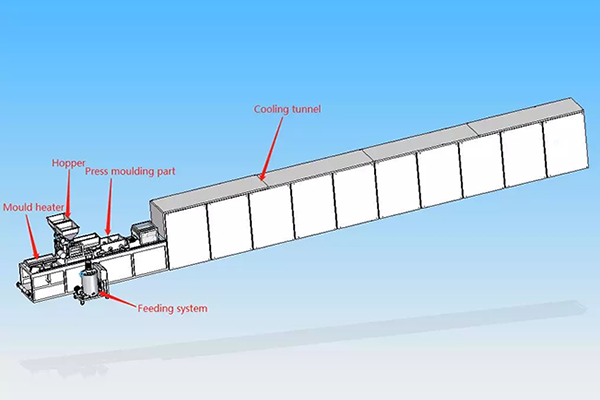

The full automatic oatmeal chocolate machine include oat chocolate making machine and cooling tunnel. It can produce all kinds of new style chocolate product in different shaped.Equipment using program control, sutomatic cereals and chocolate syrup.Under continuous automatic control of mixing material into the molding, cooling products under pneumatic beat emerge from the mold.

●Main Feature

●we can provide 60 hz motor.It is suit for your countries' voltage

●we can dispatch the technical engineer for machine's assembly,installation and all related works required to make the machine functional

●we provide maintenance after the warranty period and during the equipment maintance, you need to bear the technical engineer round-trip air ticket , accommodation ,catering,etc

●PLC control, auto-frequency control

●man-machine touch interface to detect the levels of the liquid and solid material. Overload protection to alarm when there is something wrong, and to show it on the touch screen

●programming storage of the products to change the chocolate color and products every 15 minutes. More stable when running with the prescription

●separated heating and control system. The heating system keeps the chocolate in constant temperature when the control system is powered off, so the service life of the control system is longer.

●made of stainless steel ,and matched with special accessories like SMC non-inductive magnetic cylinder, which can meet the food sanitary requirement

●adopted with the imported technology, we improve our machines according to the after service and testing report.

●equipped with 2 high precision cam rotor pumps to mix the material continuously. The batching system and the high precision cam rotor pumps can keep the stable proportion of the chocolate during producing

●during the production, the mixing materials can be detected by the sensor, and supplemented by the transducer. The whole producing process is controlled by the sensor, and there is no need to stop.

●Picture: